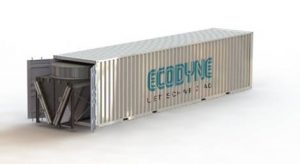

Ultra Compact Air Cooled Heat Exchangers (ECO-TAC)

Built from the ground up to provide the lowest Total Acquisition Cost for the power industry

Ultra compact, modular and custom-engineered ECO-TAC coolers provide the lowest cost for power industry applications.

Advantages

Lowest Total Acquisition Cost

- Ultra-compact, modular and standardized coolers

- Sea-freight in standard containers

- Savings of 20-30% on Total Acquisition Cost

Modular design

Engineered to Perform

Ecodyne engineers your Air Cooled Heat Exchanger (ACHE) system using modular building-blocks to meet your project specific requirements, including:- Duty and outlet temperature

- Footprint

- Power consumption

- Noise level (sound power or pressure)

Factory assembled and tested

Lowest project risk

ECO-TAC coolers are fully factory assembled and tested in order to eliminate risks onsite.

Drag-&-Drop installation

Lowest onsite costs and risk

Drag-&-Drop means low onsite costs and risks: No welding required onsite; Bolt together structure; Factory assembled piping spools; Easy erection.

Turnkey systems

Reduce interfaces to eliminate risk

Turnkey systems are available with a full range of accessories: Handrail and ladders, interconnecting piping, pump-skids, expansion tanks and chemical dosing stations.